Description:

(H) GW4 outdoor high-voltage high-altitude switch is used for outdoor high-voltage electrical equipment with three-phase AC 50Hz, for the line to be divided under voltage and no load.

And the electrical isolation of the high-voltage busbars, circuit breakers and other electrical equipment and the charged high-voltage lines can also be used to open and close small capacitors or inductor currents.

An insulation distance that meets safety requirements is provided when the knife is in the normal opening position. Widely used in 35-220kV substation.

Features:

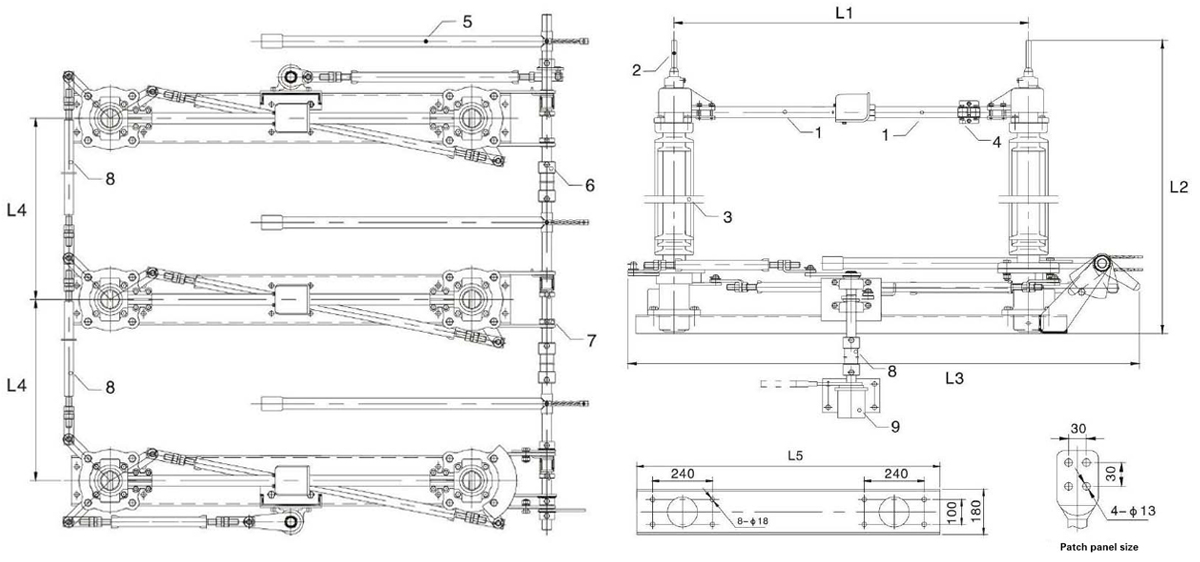

1. The isolating switch is a double-column horizontal rotary type, which is composed of a base, a post insulator, a terminal block, a left and right contact assembly, and a grounding knife;

2. The shaft socket is used between the finger and the finger socket, and the copper soft connection is used between the terminal board and the contact rod, so that the main circuit resistance of the product is greatly reduced compared with the old structure;

3. The lower ends of the two post insulators are fixed on the rotating disc at the upper end of the bearing housing, and the left and right contacts are respectively fixed on the upper end of the post insulator, and the rotating mechanism is driven by the operating mechanism, so that the strut drives the contact arm to rotate 90 degrees, and the other strut The rotating disk is rotated by 90 degrees while being pulled by the connecting and connecting rods, so that the blade is opened or closed to one side. The contact opening distance is large, and there is a sufficient amount of insulation isolation fracture to ensure its safety;

4. It adopts rolling shaft transmission, which is easy to operate, flexible to rotate, and easy to open and close;

5. The product has three modes: ungrounded, single grounded, and double grounded. There is a reliable mechanical interlock between the spindle and the ground to ensure its safety;

6. With CJ2 automatic operating mechanism or CS-17G manual mechanism, etc., can be attached to the electromagnetic lock. The positioning device on the operating mechanism can ensure that the contact and the static contact are in the correct contact position or the breaking position.

|

Type

|

|

GW4-40.5

|

GW4-72.5

|

GW4-126

|

|

Rated voltage

|

kV

|

40.5

|

47.5

|

126

|

|

Rated current

|

A

|

630

|

1250

|

630

|

1250

|

630

|

1250

|

|

4S Rated short-time withstand current

|

kA

|

20

|

31.5

|

20

|

31.5

|

20

|

31.5

|

|

Rated peak withstand current

|

kA

|

50

|

80

|

50

|

80

|

50

|

80

|

|

1 min power frequency withstand voltage

|

kV

|

Ground 95,

fracture 110

|

Ground 160,

fracture 176

|

Ground 185, fracture 210

|

|

Lightning impulse withstand voltage

|

kV

|

Ground 185,

fracture 215

|

Ground 350,

fracture 385

|

Ground 450, fracture 520

|

|

Rated frequency

|

Hz

|

50

|

50

|

50

|

|

Terminal block static mechanical load

|

N

|

750/400/500

|

750/400/500

|

1000/750/1000

|

|

Insulator mechanical strength

|

Porcelain pillar

|

kN

|

Bending resistance: 4;

anti-twist: 2

|

Bending resistance: 4;

anti-twist: 2

|

Bending resistance: 4;

anti-twist: 3

|

|

Composite pillar

|

Bending resistance: 10;

anti-twist: 5

|

Bending resistance: 6;

anti-twist: 3

|

Bending resistance: 12.5;

anti-twist: 5

|

|

Pillar insulator creepage ratio (mm)

|

Porcelain pillar

|

mm

|

III Antifouling 1020mm

|

III Antifouling 1830mm

|

III Antifouling 3150mm

|

|

Composite pillar

|

III Antifouling 1020mm;

Ⅳ Antifouling 1256mm

|

III Antifouling 1830mm

|

III Antifouling 3150mm

|

|

Mechanical life (Times)

|

|

Times

|

2000

|

2000

|

2000

|

|

Ⅰ、Ⅱ Grounding switch

|

2s short-time withstand current

|

kA

|

8、20

|

8、31.5

|

8、20

|

8、31.5

|

8、20

|

8、31.5

|

|

Peak withstand current

|

kA

|

20、50

|

20、80

|

20、50

|

20、80

|

20、50

|

20、80

|

|

Product monopole weight

|

KG

|

≈200

|

≈220

|

≈250

|

|

Matching agency

|

|

Manual mechanism: CS14, CS14G; motor model: CJ5, CJ6

|

![]() Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province

Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province![]() 0591-22806687 0591-22806697

0591-22806687 0591-22806697![]() 0591-22806667

0591-22806667