Description:

NEL series self-locking strain clamp is a patented product developed by our company according to the development needs of the power market. It is suitable for 35 ~ 500KV steel core aluminum stranded wire strain segment connection.

This series of products has the advantages of easy installation (no tools such as hydraulic pliers), no damage to the wires, low wire loss, significant energy saving effects, self-locking, maintenance-free, high mechanical strength, etc.

And has passed the test of the National Power Line Equipment Quality Inspection and Testing Center, the grip strength of the wire has reached 65% of the wire breaking force, and the damage load has reached 95% of the wire breaking force.

Features:

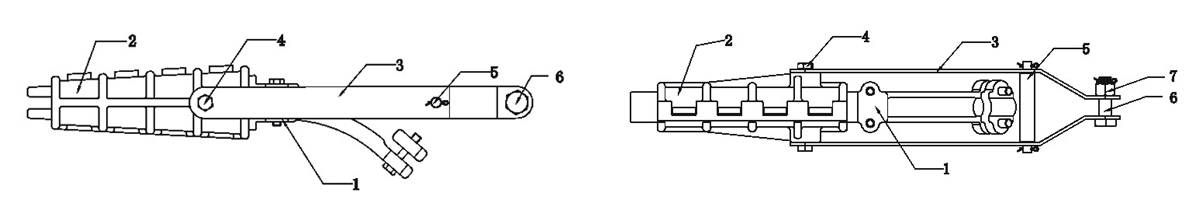

A. Apply the self-tightening principle of the model. When two opposite inner molds in the housing are pulled by the wire, they can move closer to the inside to increase the grip of the wire. The grip force is proportional to the pull of the wire and persists. , Effectively avoid the occurrence of wire slippage, and has the advantage of maintenance-free.

B. The shape of the clamp is two corresponding grooved structures, which can form a very strong wedge-shaped housing after fitting. When the inner wedge is inserted, it can prevent it from separating and has a self-locking function. The housing adopts high strength. Aluminum alloy die-casting, no hysteresis, eddy current loss, the county has the advantage of energy saving.

C. The inner mold is made of high-strength aluminum alloy. One side of the inner mold uses a lead wire slot and a fixed pressure plate, and bends downward in a certain arc, which increases the grip strength and prevents the wires from hitting the pull plate.

D. The pull plate is fixed by transverse screws, which can rotate 360 degrees, which greatly facilitates installation, storage and transportation; and there are safety bolts to prevent the screws from loosening.

E. Due to the light weight of the product, no tools such as hydraulic pliers are needed for installation, which is convenient for construction on iron towers, and the installation speed is particularly fast. Even in mountainous and wilderness environments where transportation and construction are not convenient, it does not affect the construction. It is the best for line repair. select.

|

Type

|

Internal wedge clamp range

(mm)

|

Applicable lead model LGJ-

|

Applicable lead (no peeling installation)

|

Nominal failure load (kN)

|

|

Overhead insulated hard copper wire

|

Overhead insulated steel wire

|

|

1kV

|

10kV

|

1kV

|

10kV

|

|

NEL - 41

|

Φ 12.0 ~ 14.0

|

10/40、95/15~20

|

70

|

16、25

|

50/8、70/10

|

16/3

|

≥50

|

|

NEL - 42

|

Φ 14.0 ~ 16.5

|

120/7~25、150/8

|

95

|

35、50

|

95/15

|

25/4、35/6

|

≥50

|

|

NEL - 43

|

Φ 16.5 ~ 19.0

|

150/20~35、185/10~30

|

120、150

|

70

|

120/20

|

50/8、70/10

|

≥70

|

|

NEL - 44

|

Φ 19.5 ~ 22.0

|

185/45、240/30~40

|

185

|

95、120

|

150/20、185/25

|

95/15、120/20

|

≥90

|

|

NEL - 55

|

Φ 23.0 ~ 24.5

|

300/15~50

|

240

|

150、185

|

240/30

|

150/20

|

≥110

|

|

NEL - 56

|

Φ 26.5 ~ 28.0

|

400/25~50

|

-

|

240

|

-

|

185/25、240/30

|

≥130

|

|

![]() Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province

Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province![]() 0591-22806687 0591-22806697

0591-22806687 0591-22806697![]() 0591-22806667

0591-22806667