Description:

Suspension clamps are mainly used for overhead power lines. Wires are suspended from insulators or lightning conductors are suspended from pole towers through connection fittings.

Traditional malleable cast iron clamps have the disadvantages of large hysteresis loss, large hole current loss, and bulky products. The aluminum alloy clamp has the advantages of extremely small hysteresis loss and eddy current loss, light weight, and convenient construction. It meets the requirements of energy saving and consumption reduction in the national power grid transformation and construction.

When the suspension clamp is used for aluminum stranded wire and steel core aluminum stranded wire, it can be wrapped with aluminum sheathing or protective wire to protect the wire. The applicable outer diameter of the wire includes wrappings.

The energy-saving products developed by our company have passed the inspection of the Quality Inspection and Testing Center of the Ministry of Electric Power Industry, meet the requirements of GB2314 and relevant standards, and have passed the national energy-saving certification.

Percentage of suspension clamp gripping force to rated tensile force of wire:

|

Wire Class

|

Wire Structure(Aluminum Ratio)

|

Percent

|

|

ACSR

(Steel core aluminum stranded wire)

|

>1.7

|

12

|

|

4.0-4.5

|

18

|

|

5.0-6.5

|

20

|

|

7.0-8.0

|

22

|

|

11.0-20.2

|

24

|

|

Steel stranded wire

|

Ultimate strength 1176-1274

|

14

|

|

Aluminum stranded wire

|

|

30

|

|

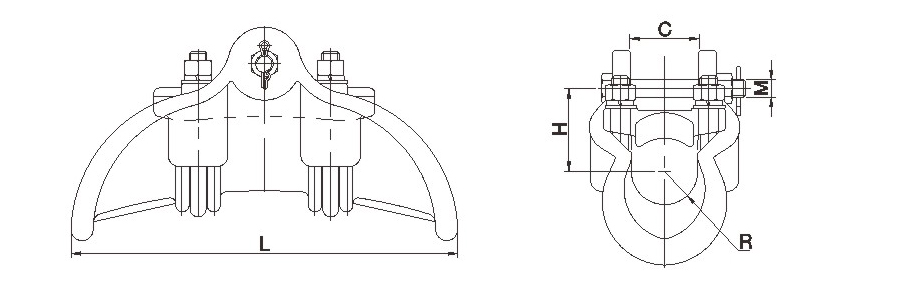

Type

|

Enterprise Standard Model

|

Suitable for Wire Diameter Range

(Including Wrapped)(mm)

|

Main Dimensions

(mm)

|

Nominal Failure Load

(kN)

|

Weight

(kg)

|

|

H

|

L

|

R

|

C

|

M

|

|

CS-51

|

CGF-7054

|

40.0~54.0

|

73

|

350

|

27

|

56

|

16

|

70

|

5.6

|

|

CS-57

|

CGF-7060

|

53.0~60.0

|

75

|

350

|

30

|

62

|

16

|

70

|

6.2

|

The clamp body and pressure plate are made of aluminum alloy, the closed pin is made of stainless steel, and the rest are made of hot-dip galvanized steel.

|

![]() Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province

Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province![]() 0591-22806687 0591-22806697

0591-22806687 0591-22806697![]() 0591-22806667

0591-22806667