Description:

Composite post insulator has good bending resistance, strong anti-fouling ability, strong impact resistance, good shock and anti-brittle performance, small size, light weight, easy installation, maintenance-free, no need for manual cleaning, and interchangeable with porcelain. Sex.

|

Type

|

Rated voltage

(KV)

|

Rated bending load

(KN)

|

Structural height

(mm)

|

Min arc distance

(mm)

|

Min nominal creepage distance

(mm)

|

Lightning full wave impulse withstand voltage

≥ (kV)

|

Frequency withstand voltage

(kV)

|

Number of holes x Aperture - center of the hole

|

IMG No.

|

Weight

(kg)

|

|

Upper mounting hole size

|

Lower mounting hole size

|

|

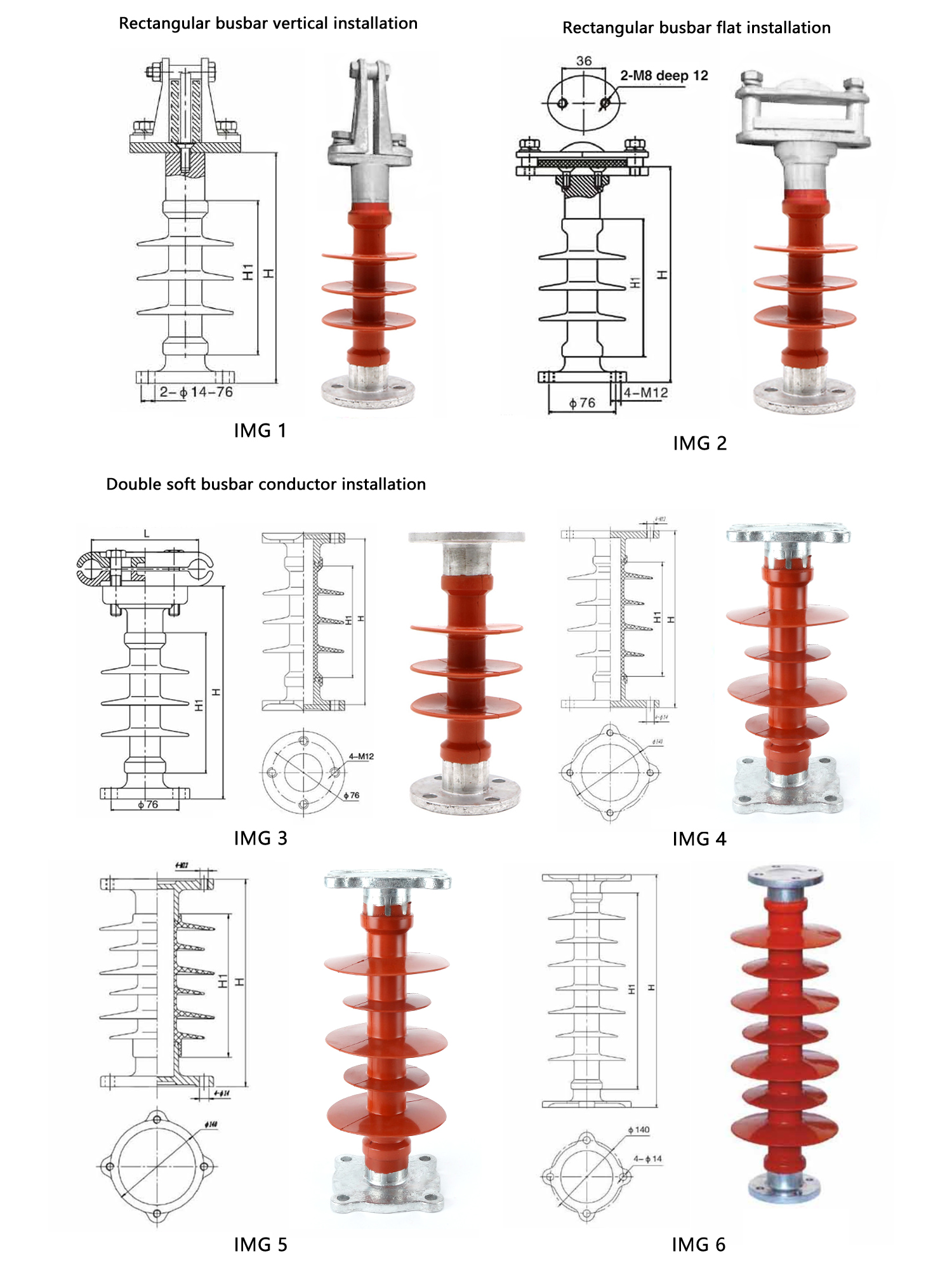

FZN4-12/4-M10

|

12

|

4

|

230±3

|

125

|

330

|

75

|

30

|

M10

|

2 x Φ 14 –Φ 76

|

1

|

0.8

|

|

FZN4-12/4-M16

|

12

|

4

|

230±3

|

125

|

330

|

75

|

30

|

M16

|

2 x Φ 14 –Φ 76

|

1

|

0.8

|

|

FZSW4-12/4-2 x M8

|

12

|

4

|

230±3

|

125

|

330

|

75

|

30

|

2 x M8-Φ 36

|

4 x M12-Φ 76

|

2

|

1.4

|

|

FZSW4-12/4L-IEC

|

12

|

4

|

215±3

|

125

|

330

|

75

|

30

|

4 x M12-Φ 76

|

4 x M12-Φ 76

|

3

|

1.8

|

|

FZSW4-12/8

|

12

|

8

|

265±3

|

155

|

430

|

75

|

30

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

3

|

4.6

|

|

FZSW4-24/8L-IEC

|

24

|

8

|

310±3

|

200

|

540

|

150

|

60

|

4 x M12-Φ 76

|

4 x M12-Φ 76

|

4

|

2.9

|

|

FZSW4-24/8

|

24

|

8

|

310±3

|

200

|

540

|

150

|

60

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

4

|

4.7

|

|

FZSW4-24/10

|

24

|

10

|

310±3

|

200

|

540

|

150

|

60

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

4

|

5.2

|

|

FZSW4-24/16

|

24

|

16

|

310±3

|

200

|

732

|

150

|

60

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

5

|

5.8

|

|

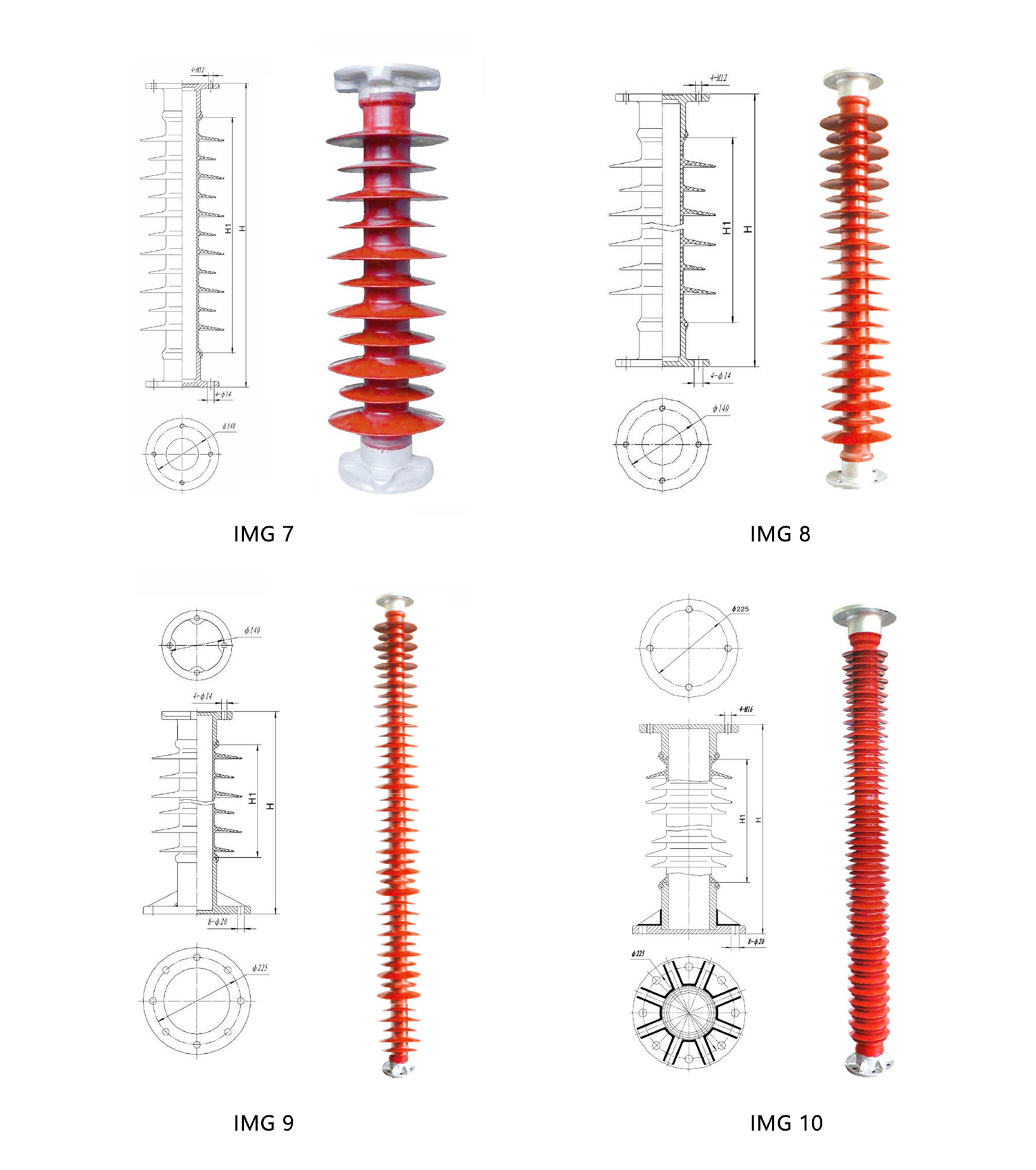

FZSW3-40.5/6L(IEC)

|

40.5

|

6

|

445±3

|

340

|

920

|

200

|

80

|

4 x M12-Φ 76

|

4 x M12-Φ 76

|

6

|

3.6

|

|

FZSW3-40.5/6

|

40.5

|

6

|

445±3

|

340

|

920

|

200

|

80

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

6

|

5.5

|

|

FZSW4-40.5/10L

|

40.5

|

10

|

445±3

|

340

|

1260

|

200

|

80

|

4 x M12-Φ 140

|

4 x M12-Φ 140

|

6

|

7.1

|

|

FZSW3-40.5/16L

|

40.5

|

16

|

500±3

|

370

|

1085

|

200

|

80

|

4 x M12-Φ 140

|

4 x M12-Φ 140

|

6

|

7.6

|

|

FZSW3-40.5/6-475(IEC)

|

40.5

|

6

|

475±3

|

370

|

1020

|

200

|

80

|

4 x M12-Φ 76

|

4 x Φ14-Φ 76

|

6

|

5.5

|

|

FZSW3-40.5/6-475

|

40.5

|

6

|

475±3

|

370

|

1020

|

200

|

80

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

6

|

5.5

|

|

FZSW3-40.5/8-475

|

40.5

|

8

|

475±3

|

370

|

1020

|

200

|

80

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

6

|

6.0

|

|

FZSW4-40.5/10-475

|

40.5

|

10

|

475±3

|

370

|

1260

|

200

|

80

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

6

|

7.1

|

|

FZSW4-72.5/4L

|

72.5

|

4

|

790±3

|

650

|

2400

|

350

|

160

|

4 x M12-Φ 140

|

4 x M12-Φ 140

|

7

|

10.1

|

|

FZSW3-72.5/6L

|

72.5

|

6

|

770±3

|

650

|

1850

|

350

|

160

|

4 x M12-Φ 140

|

4 x M12-Φ 140

|

7

|

13.2

|

|

FZSW3-72.5/8

|

72.5

|

8

|

770±3

|

600

|

1850

|

350

|

160

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

7

|

16.2

|

|

FZSW3-72.5/8L-790

|

72.5

|

8

|

790±3

|

650

|

1850

|

350

|

160

|

4 x M12-Φ 140 (Aluminum alloy)

|

4 x M12-Φ 140 (Aluminum alloy)

|

7

|

11.4

|

|

FZSW3-72.5/10

|

72.5

|

10

|

770±3

|

600

|

1950

|

350

|

160

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

7

|

18.5

|

|

FZSW3-72.5/12.5

|

72.5

|

12.5

|

770±3

|

600

|

1950

|

350

|

160

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

7

|

20.1

|

|

FZSW4-126/4

|

126

|

4

|

1220±5

|

1080

|

3510

|

550

|

160

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

8

|

11.9

|

|

FZSW3-126/8

|

126

|

8

|

1220±3

|

1050

|

3150

|

550

|

230

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

8

|

22.5

|

|

FZSW3-126/10

|

126

|

10

|

1220±3

|

1050

|

3150

|

550

|

230

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

8

|

22.5

|

|

FZSW3-126/12.5

|

126

|

12.5

|

1220±3

|

1050

|

3500

|

550

|

230

|

4 x M12-Φ 140

|

4 x Φ14-Φ 140

|

8

|

27.5

|

|

FZSW3-126/16

|

126

|

16

|

1220±3

|

1010

|

3500

|

550

|

230

|

4 x M16-Φ 225

|

8 x Φ 20 –Φ 225

|

8

|

50.5

|

|

ZSW3-252/6K

|

252

|

6

|

2300±5

|

2070

|

6300

|

1050

|

460

|

4 x Φ14-Φ 140

|

8 x Φ 20 –Φ 225

|

9

|

54.3

|

|

ZSW3-252/8

|

252

|

8

|

2300±5

|

2000

|

6700

|

1050

|

460

|

4 x M16-Φ 225

|

8 x Φ 20 –Φ 225

|

10

|

75.3

|

Ordering:

Ordering:

1. When ordering, you need to specify the product specifications, model and quantity;

2. need to clearly point out the two center hole distance, if not clear, according to IEC and other relevant standards.

![]() Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province

Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province![]() 0591-22806687 0591-22806697

0591-22806687 0591-22806697![]() 0591-22806667

0591-22806667