Description:

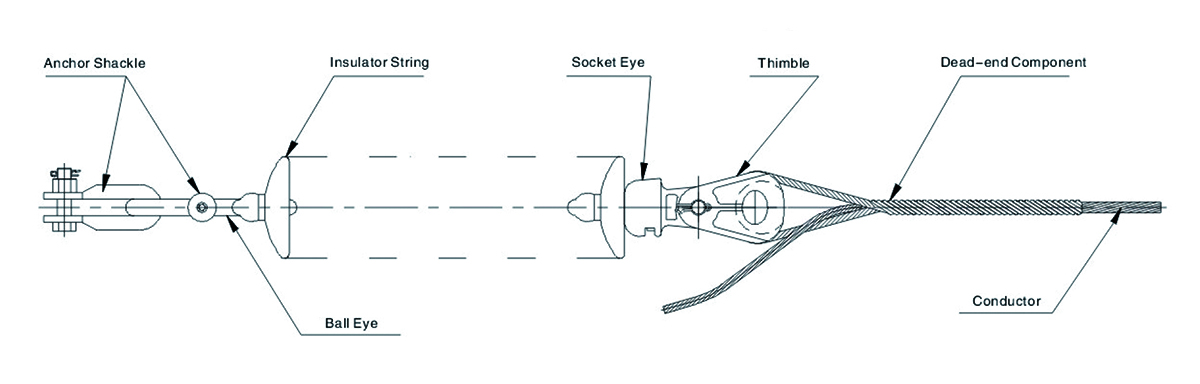

The Preformed tension clamp is used for the bare conductor or overhead insulated conductor of the transmission and distribution line, and it is fully tensioned. The conductor is connected to the tension-resistant tower, which can replace the conventional bolt-type tensile clamp and compression type tensile strength. The wire clamp and the model are resistant to the wire clamp, and the product reliability and economy are superior.

The Preformed tension clamp has a simple structure and is matched with the heart-shaped ring. After installation, the tubular structure formed by the legs of the pre-twisted wire is naturally wound around the wire to generate a strong grip force, and the grip strength of the wire is increased. The large, innovative construction and precision design give the wire tensile clamp a reliable performance.

The clamps are usually made of aluminum clad steel, galvanized steel wire and the like.

Product classification:

Preformed conductor tension clamp

Preformed ground wire tension clamp

Preformed cable tension clamp

Feature:

1. The strength of the clamp is high, the grip strength is reliable, and the grip strength of the wire is increased. The grip strength of the clip is not less than 95% CUTS (the twisted wire calculates the breaking force).

2. The wire clamp has uniform stress distribution on the wire and does not damage the wire, which improves the anti-vibration ability of the wire and greatly prolongs the service life of the wire.

3. Simple installation and easy construction. It can greatly shorten the construction time and can be operated by one person without any special tools.

4. the installation quality of the clamp is easy to guarantee, can be inspected with the naked eye, no special training is required.

5. good corrosion resistance; material and wire are completely consistent, to ensure that the wire clip has a strong resistance to electrochemical corrosion.

Instructions for ordering:

1. Due to the special structure of the clamp, the clamp can only be used once after being stressed, and should not be reused.

2. The specification and type of the wire must be provided when selecting the product or ordering.

3. Do not lap the clip on the wire, but it is allowed to make the lap on the wire before and after the wire clip.

4. The direction of rotation of the clamps and wires should be consistent. The standard clamp is right-handed and must be declared if left-handed.

5. This product is a precision device. To ensure proper installation, it should be stored in the packing box to prevent impact or heavy pressure during handling to avoid deformation of the pre-twisted wire.

6. When working on or near a live line, special care must be taken to prevent electric shock.

![]() Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province

Inside Road & Administration Industry & Trading Garden,Houshan Industry Area,Fuzhou City,Fujian Province![]() 0591-22806687 0591-22806697

0591-22806687 0591-22806697![]() 0591-22806667

0591-22806667